PUWER ’98

What is PUWER? What are your PUWER obligations? Find out more here.

All the below articles are subtopics of the PUWER Guide

When your machine has specific risks you need measures to prevent unauthorised use.

Often work equipment, despite the best efforts of designers, will have specific risks. A specific risk is one where the designer has tried and exhausted the possibility to make the machine safe by eliminating or removing hazards by safe design, or adding safeguards and complementary protective measures such as emergency stops and devices for isolation of the supply.

What remains are “specific risks” and the designer will provide information to the user to highlight these risks in the manual and on the work equi...

PUWER Inspection Learning

Measures to prevent unexpected start up during routine tasks in hazard zones protected by interlocked movable guard or protective devices.

Where access to the hazard zone is required during normal operation, and the cumulative frequency of tasks is weekly or greater the machine designer may choose to use an interlocked movable guard or protective devices (to initiate an appropriate control response to achieve a safe condition for dangerous moving parts).

Typical Control Measures

When interlocked movable guards are used to prevent access to the hazard zone during norm...

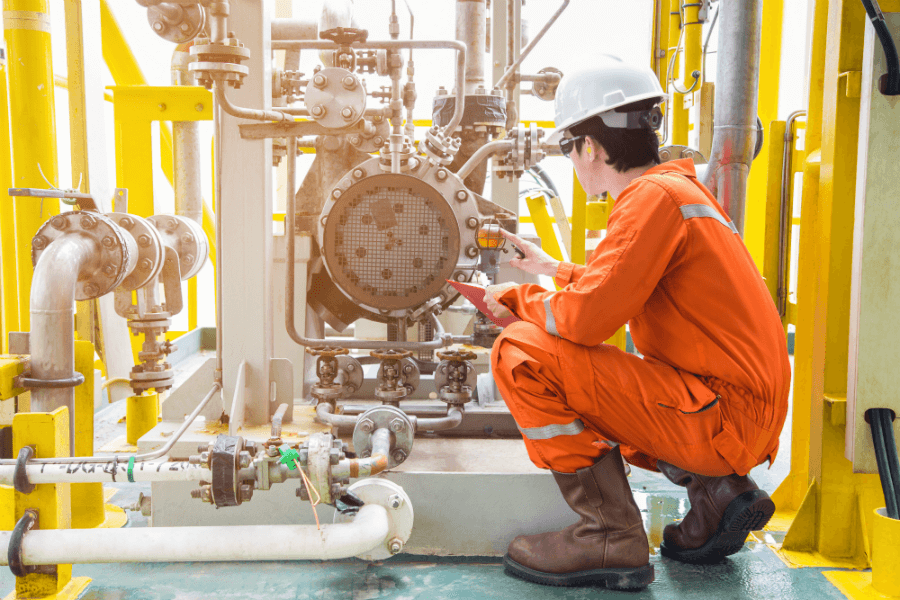

We’re all aware that maintaining a safe business environment is essential to any organisation, and those organisations involved in the industrial sector (especially those involved in the Oil & Gas) need to take it even more seriously. Regular maintenance and inspections need to be in place to avoid unplanned shutdowns and to protect citizens and the environment from industrial hazards.

A large amount of guidance has been developed for determining appropriate levels of inspection in proportion to the risk of failure and its consequences, with regards to pressure systems, storage tanks and cont...

Responding to Defects

As a result of statutory inspections required by PUWER, COSHH, DSEAR, LOLER and others there are going to be defects found. After all, that is the point. For each defect you will have a risk estimation provided to help you (the user) make good decisions about where to apply resources to protect your workers and others most effectively.

The problem comes where you have a large operation with many instances of defects. It would be great if resources were available to cover 100% of actions that are required but that isn't a reality for most businesses. Even if you have the c...

What is ACOP?

ACOP is the acronym which is widely used for ‘Approved Code of Practice’ and describes the recommended methods that should be used (or standards to be met) to comply with Health and Safety legislation. The Health and Safety at Work Act impose these regulations and duties, and it is advised that the Code (which relates to your H&S area) should be followed in order to comply with the law.

There are many ACOP’s, and each one is approved by the Health and Safety Executive. Each Code gives detailed information and advice on how to comply with the law and has it’s own legal status. If ...

If your role includes responsibility for work equipment in the workplace, then you will most likely be bowled over by the amount of legislation and regulations which exist to ensure you keep your work equipment safe (and your organisation avoiding HSE intervention!).

A common question is ‘What is the difference between PUWER & LOLER?’. Both sets of regulations are often referred to together because they do have some overlap. However, it is important to recognise that LOLER only applies to lifting equipment (e.g. a hoist, winch, crane and the lifting elements of other work equipment and accesso...

What is PUWER?

Certain types of work equipment that Regulation 6 of PUWER still applies to also have additional inspection requirements attached to them under separate legislation. Compliance with these separate requirements fulfils the general Regulation 6 inspection duty under PUWER.

You probably already know that ensuring regulatory compliance lies within the responsibilities of the employer but it can often be difficult to keep track of all compliance activities and operate a reliable, auditable risk management system, especially when it comes to a sizable project, assembly of machines or ...

This is a short, succinct PUWER inspection guide for the person actually tasked with doing the PUWER inspections and resulting risk assessment (PUWER Assessor).

We have stripped out the jargon and legal bumph leaving only what is relevant to you as you look at the machine or work equipment.

Some aspects of the safe system of work (SSoW) which must be considered under PUWER have been removed as they are not applicable or practical to apply at the point of inspection. Some other arrangements should be made for these.

Summary of PUWER Regulations

Regulation 1 – Citation and commencement (IGNORE)

...What does PUWER tell us?

Regulation 6 of PUWER places a duty on the owners of work equipment to ensure it is appropriately inspected and maintained by a competent person. However, the regulations do not provide a definition of what ‘competent person’ means.

If you would like to learn more about PUWER than read our Guide: The ultimate guide to PUWER

What is the purpose of a PUWER inspection?

The HSE’s approved code of practice for PUWER states:

“The purpose of the PUWER inspection is to identify whether the work equipment can be operated and maintained safely and that any deterioration can be d...